Expertise in nuclear technology - a lasting strength of the German economy

Both the German public and potential clients on the international market are well aware of the chequered history of nuclear energy in Germany and the now completed policy of phasing out nuclear power generation. It is not uncommon - unless there are long-standing business relationships - for "German" to be synonymous with criticism of nuclear energy and the phase-out. What is far less well known is that Germany has not only built up an almost comprehensive portfolio of expertise in nuclear energy and nuclear technology in the past, but above all that a large part of this expertise is still available today and can be called upon directly in industrial practice and for research.

Where does the industry's expertise lie in Germany? Here it makes sense to start with the most important field of activity in Germany today, the dismantling of nuclear facilities. Although this puts the cart before the horse in terms of the life cycle of a plant, expertise and capacities in dismantling have been greatly expanded in recent years for unavoidable reasons of market development and customer requirements on the part of German electricity supply companies (EVU).

An astonishing number of 27 nuclear power plants of different types and sizes are currently being dismantled in Germany, at very different stages of the dismantling process, up to and including only formally maintained status as a dismantling facility. One plant - the THTR in Hamm-Uentrop - is in safe enclosure, which no longer exists as a statutory dismantling option, five plants have been shut down but are not yet being dismantled and three plants have been completely dismantled.

On the one hand, industrial expertise lies with several large project partners of the energy supply companies, who are commissioned with larger trades that require specialised know-how. These include the manufacturing companies Framatome and Westinghousethe container, conditioning and waste management specialist GNS Company for Nuclear Serviceswhich has built up an extensive dismantling portfolio, a long-established nuclear technology company in Germany such as NUKEM Technologiesthe broad-based power plant and systems service provider Iqony (formerly STEAG), which emerged from Energiewerke Nord and the dismantling of the Greifswald nuclear power plant. Disposal plant for nuclear facilities and Power plants Heidelberg Bouygues Construction. These companies can take on the general planning for the entire dismantling process or large trades, master the entire portfolio of dismantling and decontamination techniques, have complex plant technology and personnel for challenging tasks such as the dismantling of core internals and reactor pressure vessels and offer conditioning and waste management solutions. The company also offers support for supervisory processes and the organisation of radiation protection. Framatome, Westinghouse and the Siempelkamp NISwhich also offers a range of other dismantling services such as detailed activation analyses, also carry out primary circuit decontamination in preparation for dismantling and to minimise the radiological exposure of employees. In the NIS technical centre, it is possible to develop and test customised dismantling solutions together with customers. The company, which specialises in a wide range of nuclear technology tasks Bilfinger Noell also offers a comprehensive portfolio for dismantling, including a complete residual material processing centre for installation in the dismantling plant.

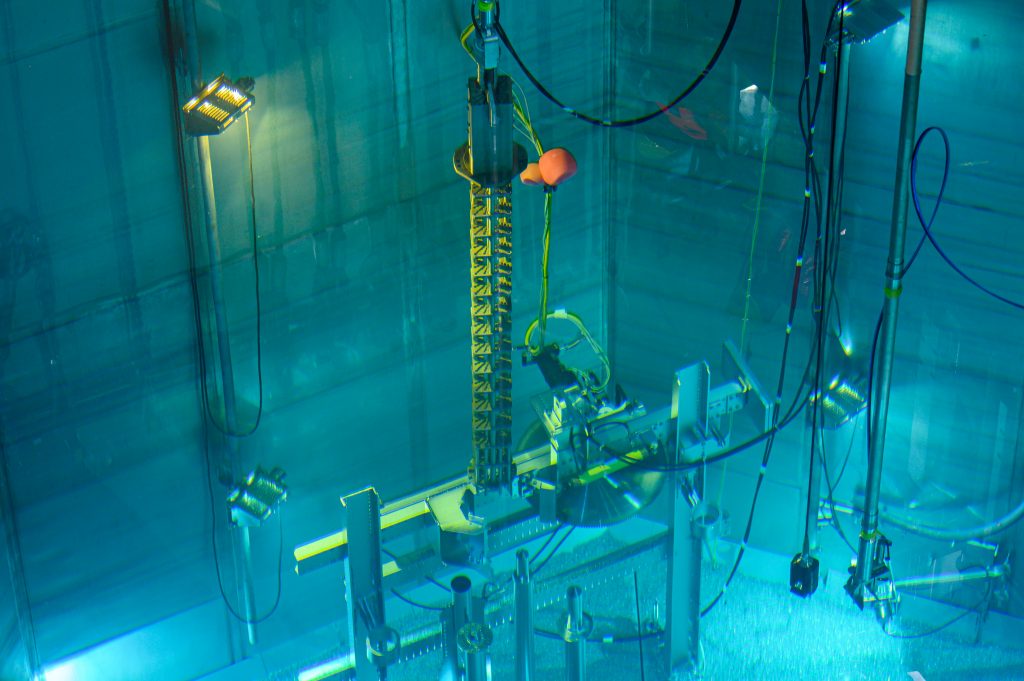

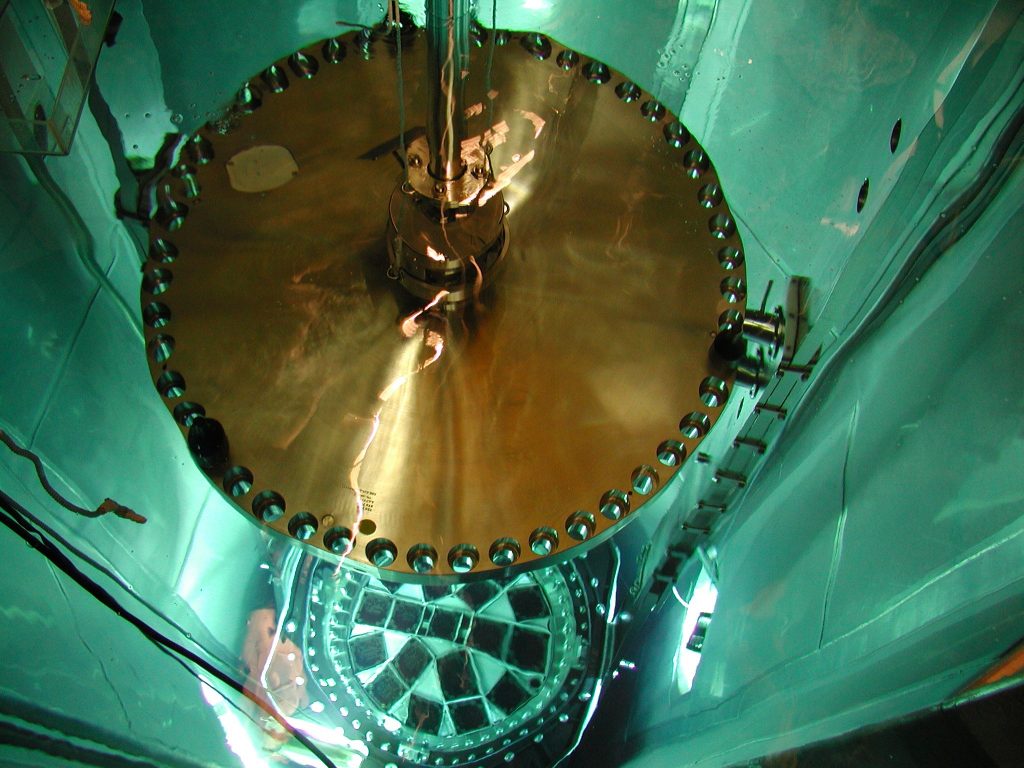

Dismantling the core internals at the Unterweser NPP Copyright: PreussenElektra

These integrating companies are joined by numerous specialised companies that offer systems or services in connection with nuclear decommissioning. These include the radiation protection specialist Safetecwhich also offers consulting and waste disposal services and the operation of waste processing centres, the Institute for Environmental Technologies and Radiation Protection (IUS)the planning and documentation service provider for decommissioning and radiation protection, among other things Dornier Groupthe provider of decontamination, clearance, radiological characterisation and radiation protection services Brenk system planningthe subsidiary of the industrial services provider ROBUR Industry Service Group specialising in nuclear decommissioning, SAT Nuclear Technologywhich specialises in water treatment, cleaning and blasting work as well as robotics. RST. The Orano offers concept development and planning in the areas of dismantling, packaging and disposal as well as specific dismantling work for complex tasks such as dismantling components for core internals and RPVs. Another service relevant to dismantling is heavy and special transport, which is provided by the August Alborn and, with a comprehensive range of nuclear engineering services including decommissioning planning and radiation protection, from the Orano NCS are offered.

Many of the companies mentioned are already active in the international dismantling market. Once the extensive order volumes in Germany have been processed in relevant parts, the dismantling companies/dismantling divisions of German companies and company locations will be available to support the energy supply companies and research institutions in other countries to an even greater extent and will be able to draw on the extensive practical expertise from dismantling in Germany. The fact that most European countries that use nuclear energy have abandoned a phase-out policy and broad-based programmes to extend the lifetimes of nuclear power plants means that this business area can continue to exist for quite a long time.

In tablet production, the uranium dioxide powder is processed into tablets. The so-called green compacts are sintered in the oven at a temperature of 1,780°C for two to three hours. They are then ground to their target diameter with high precision.

Copyright: ANF

The nuclear fuel supply companies, the so-called front end, were and are not affected by the phase-out of nuclear energy for power generation. On the one hand, this is the Urenco Germanythe German part of the international uranium enrichment provider Urenco Ltd. Advanced Nuclear Fuelsa subsidiary of Framatome, which manufactures and develops fuel elements for a large number of light water reactors and offers systems and processes for the optimisation of production and product control in the area of fuel elements. Following the decision to accelerate the phase-out of nuclear power generation, ANF has also received orders for the dismantling and disassembly of fuel elements that have not yet been used and has expanded its business in the development and construction of manufacturing technologies and the production of special products such as gadolinium- and chromium-doped fuel pellets. The production and maintenance of transport casks for unirradiated fuel elements was also added to the service portfolio. The site in Lingen has a production capacity of 650 tonnes of enriched nuclear fuel, corresponding to 18.3 percent of the European production capacity for light water reactor fuel elements. ANF also includes the production of fuel element structural parts in Karlstein/Main.

With a capacity of 3,700 tSW/a, Urenco's German site in Gronau has a 17.5 per cent share of uranium enrichment capacity in Europe, which, like capacity in fuel element production, is currently in high demand due to the efforts of Western countries to become independent of the Russian nuclear fuel supply chain. In connection with uranium enrichment in particular, the technology company ETC Germanypart of Enrichment Technology Company Limited, a joint venture between Urenco Ltd. and the Orano Group. ETC bundles the expertise of the centrifuge technology for enrichment, which was developed in Germany at the time. There are also subsidiaries for carbon fibre production (Pronexos), electricity storage with centrifuge cascades (Storenetic) and hydrogen storage (NPROXX), all of which were spun off as derivatives of uranium enrichment technology.

From the completion of the German nuclear power plant construction programme in 1989 until the phase-out of nuclear power generation, the main field of activity of the nuclear industry in Germany, as in most Western countries, was the support of plant operation through service and maintenance, recurring inspections and safety analyses, safety-related retrofits and other modernisations, the implementation of performance enhancements and, for some time now, ageing management and the facilitation of safe lifetime extensions, particularly in foreign business.

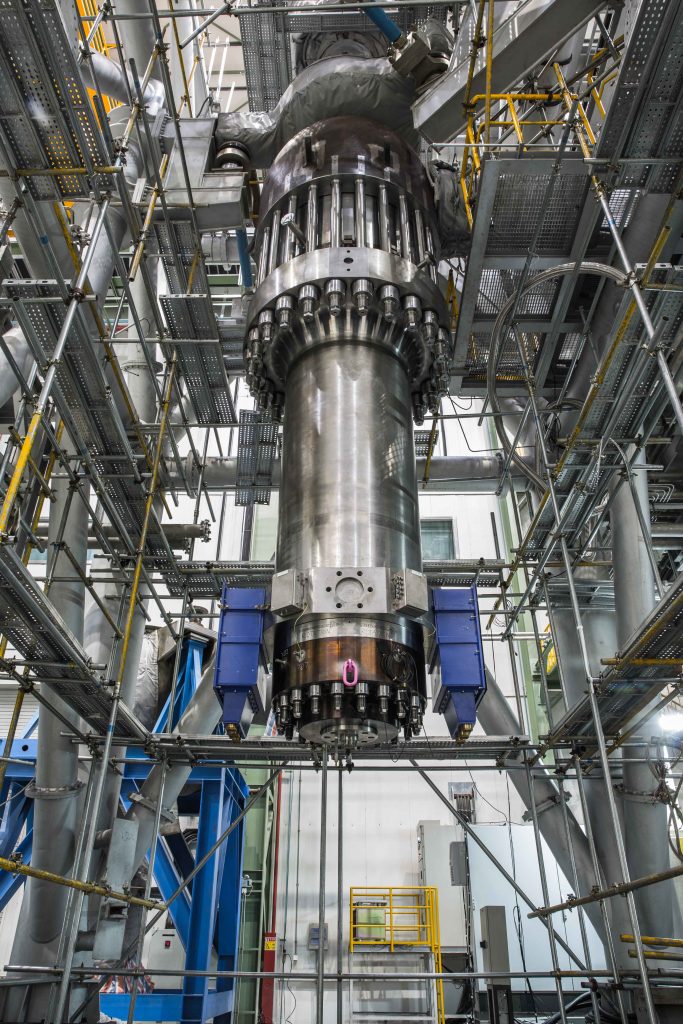

Narrow gap welding at the Framatome site in Erlangen, here for the assembly of a new steam generator to modernise a reactor in operation. Copyright: Framatome GmbH

The portfolio of these services in Germany continues to exist and lies with the Framatomethe Bilfinger Noellthe Westinghouse and the Power plants Heidelberg. Such services include plant service over the course of the life cycle, inspection, maintenance and repair, inspection work and operational support, planning and development of service structures including service documentation, the provision of highly qualified service personnel, engineering support and technical processing, spare and wear parts management, ageing management and optimisation, conversion and expansion. This area also includes safety-related retrofits such as filtered pressure relief systems or systems for residual heat removal and emergency power supply, modernisation of systems such as the digitalisation of control technology and solutions for increasing performance. The portfolio also includes safety analyses and all kinds of tests on systems and components. Framatome also offers the option of comprehensive radiochemical and material analyses as well as the use of thermal-hydraulic test facilities for component qualification and design and code validation. This is also associated with a considerable amount of industrial (safety) research. Westinghouse also offers safety solutions for nuclear facilities, and the Heidelberg power plants offer a comprehensive pipework service.

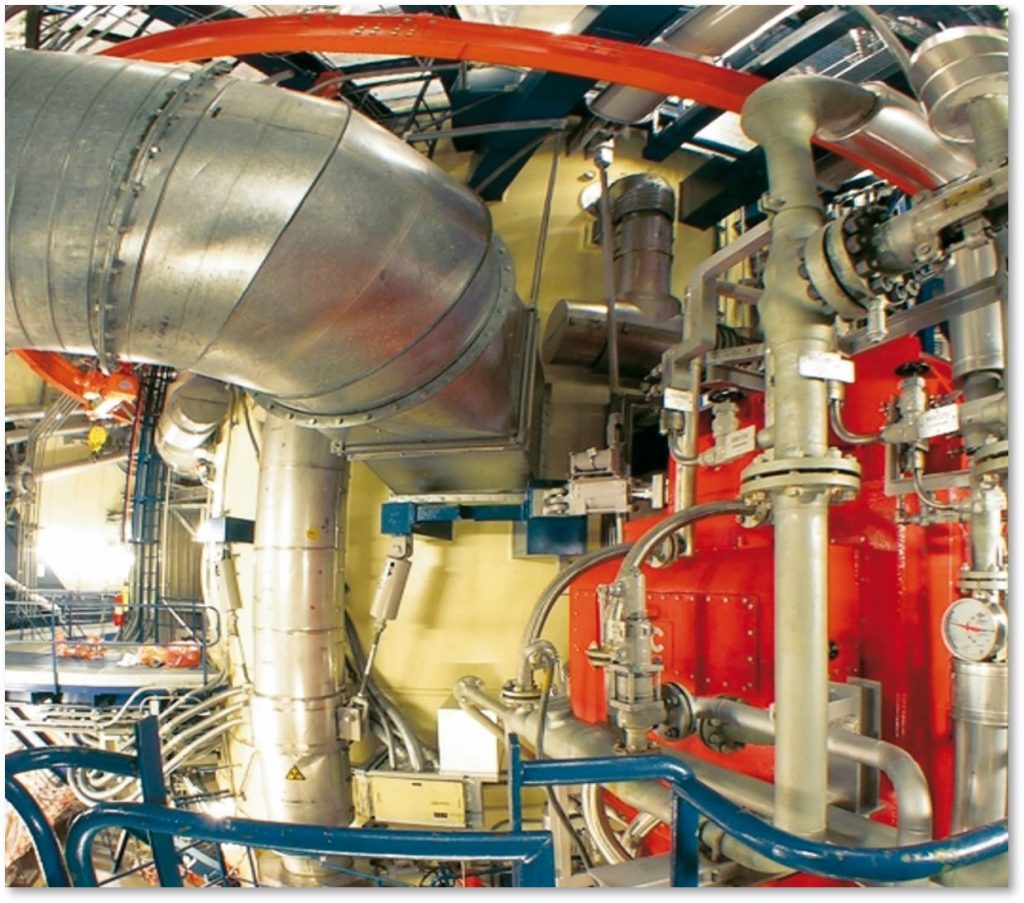

Large valve test rig at the Framatome site in Karlstein, or "GAP" for short. It is the largest valve test rig in the world and has been used for over 40 years for the qualification of large valves, e.g. live steam shut-off valves. Copyright: Framatome GmbH

Other companies that offer services in this area specialise in individual fields of activity, such as Bilfinger Engineering & Technologies pipework construction or offer a range of relevant services, such as the Siempelkamp NIS with a measurement and laboratory data management and reporting system, the fuel element information and reporting system, nuclear physics services and fuel element deployment planning in PWR and BWR, criticality analyses and shielding calculations. The NUKEM Technologies offers a comprehensive range of engineering services and complete planning and execution packages for nuclear power plants, nuclear fuel cycle facilities and other nuclear facilities in the fields of safety engineering, safety and licences, radiation protection, instrumentation and emission monitoring. Nuclear engineering and services, IT services and the planning, manufacture and supply of inspection, handling and measuring equipment. Cleaning machines and gripper systems are offered by Höfer & Bechtelwhich is also active in dismantling.

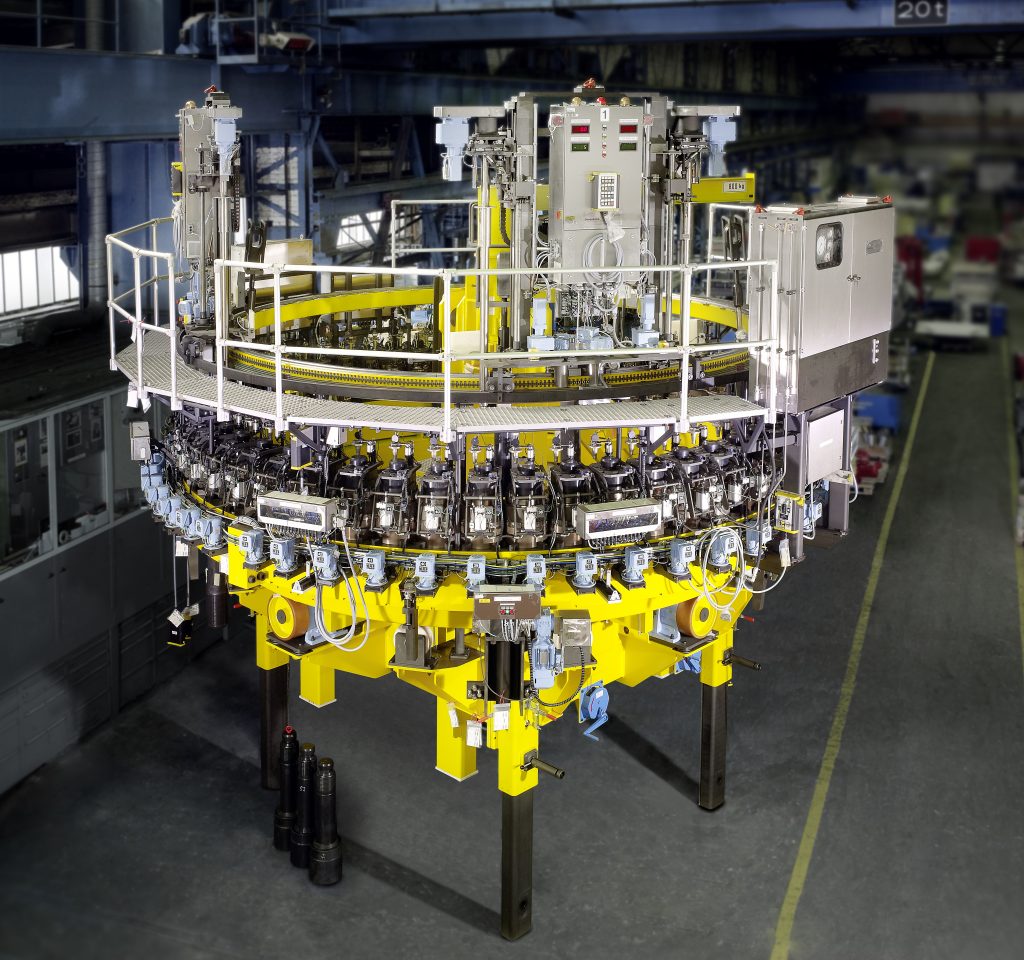

In addition to the manufacturers of nuclear power plants and companies with a wide range of nuclear technology services represented in Germany, there are also a number of specialised suppliers and component manufacturers outside of the dismantling sector. These include the globally active pump manufacturer KSBwhose product range also includes a complete range of pumps and valves for nuclear power applications as well as several models of main coolant pumps for pressurised water reactors, including shaft seal-less designs with wet rotor motors or reactor-internal pumps for boiling water reactors. The large heat pump and liquid cooler manufacturer Friotherm produces and installs liquid chillers for nuclear power plants worldwide. The ENGIE Germany supplies technical building equipment for nuclear power plants in the fields of ventilation technology, electrical engineering, fire protection technology and sprinkler systems, heating technology, industrial sanitary technology, building automation (measurement and control technology), process technology for water and compressed air supply and disposal as well as refrigeration technology. KROHNE Nuclear is a division of the KROHNE measurement technology offers flow and level measurement technology for a wide range of nuclear applications using diverse methods. The Make-up crane technology manufactures special cranes in accordance with KTA, as does Iqony. Its subsidiary Krantz in turn, specialises in air ducting, heating and cooling systems, including for the ventilation of nuclear facilities. And the Siempelkamp NIS is also active as a component manufacturer with bolt turning devices, cleaning machines and hydraulic units, but is best known for its bolt tensioning systems for reactor pressure vessel covers for pressurised and boiling water reactors and for steam generators.

Many of the services mentioned for existing nuclear power plants and the supply of components are also relevant for new construction. In fact, a considerable amount of the expertise required for the construction, commissioning and fuel supply of nuclear power plants is still available in Germany today. Two major international nuclear power plant manufacturers have sites in Germany, Framatome and Westinghouse, other companies active in new construction such as Bilfinger Noell and Power plants Heidelberg and an extensive supply chain of component and plant manufacturers, German company locations and companies have been and are involved in international new construction projects. These include the EPR projects Olkiluoto (FIN), Flamanville (F), Taishan (CN) and Hinkley Point (GB) as well as the VVER projects in Paks (H), Akkuyu (TR) and El-Daaba (Egypt). The AP 1000 projects Sanmen and Haiyang (CN), as well as Vogtle (US) have also been realised with German participation. Furthermore, a Siemens/KWU pre-convoy plant is still being completed at the Angra dos Reis site in Brazil. German companies are also involved in the new construction project Barakah (United Arab Emirates) of the South Korean KEPCO.

One of Framatome's main areas of business is control and instrumentation technology, which links the components and systems of the power plant in a complex system in accordance with regulatory and operator requirements and makes the safe operation of the plant possible in the first place. In addition, we also have the necessary expertise in the design of nuclear power plants, the design and installation of nuclear steam generator systems, the development and manufacture of fuel elements and associated components, as well as in commissioning. The field of expertise covers areas such as materials technology, mechanics, neutron physics, scientific calculations, fluid mechanics and risk and safety analyses. The portfolio also includes the design and installation of electrical systems and emergency power supply, containment and ventilation systems. These new construction services and comparable offers in connection with modernisation, maintenance, etc. are also available for research reactors of different types in accordance with the special requirements.

Test bay for safety control cabinets at the Framatome site in Erlangen. Copyright: Framatome GmbH

At Westinghouse Electric Germany, the focus of new construction activities is on engineering, such as general plant planning. Special expertise is available in Germany, particularly in control technology and waste treatment. Here, German expertise has flowed into the construction of the SRTF (Site Radwaste Treatment Facilities) of the Chinese AP1000 plants. It is worth mentioning that the Polish government has selected AP1000 technology for its future new construction projects. The first AP1000 plants in Europe will also offer German companies the opportunity to participate in these projects.

RUV - Reactor main coolant pump for pressurised water reactors of the latest generation installed in the dynamometer Copyright: KSB

The Bilfinger Noell supplies numerous components for nuclear power plants such as containment liners, safety hulls, personnel and material locks, stainless steel linings for pools, compact storage racks for radioactive materials, system components for safety systems and for reactor operation, filter changing machines and waste treatment facilities. In addition, Bilfinger Noell also offers design services and static and dynamic calculations of various types and tasks in accordance with the requirements of various nuclear regulations. One example of a complex service package is the supply and installation of the Core Melt Stabilisation System (CMSS) for EPR™ plants. The central component of this system, the core catcher, is supplied by Siempelkamp NIS. Bilfinger Engineering & Technologies, which specialises in high-pressure pipelines, is of course also involved in new builds.

Kraftanlagen Heidelberg offers a comprehensive range of engineering services from the planning and design of systems and components in nuclear facilities to expertise in technical strength problems and flow analyses, overall concepts, installation planning including building layouts for waste treatment, assembly, service and pipeline construction. The company also plans, supplies, installs and commissions process and mechanical engineering systems as well as high-quality piping systems in nuclear power plants, nuclear facilities and research facilities and remote handling technology.

Welding work at the Framatome site in Karlstein for the core instrumentation of the EPR reactor. Copyright: Framatome GmbH

In addition, the products, solutions and expertise of the above-mentioned manufacturers of systems and components for nuclear power plants can also be applied to new projects. This applies both to proven technology and to customised solutions and new developments. One example of this is the pump and valve manufacturer KSB, which is also developing corresponding components for fourth-generation reactors that are to be operated with liquid lead or liquid salt.

After a phase in which the nuclear industry in Germany focussed heavily on the dismantling of the country's power plants, the foreseeable upturn in nuclear energy in Europe means that, after decades, the construction of new plants is once again coming to the fore as a key task and an important area of business. This upturn is decisively determined by the climate policy ambitions to which the EU and most of its member states have committed themselves. In Germany, a path is being pursued to largely dispense with fossil fuels without nuclear energy, while it is an integral part of the climate and energy strategy of many of our neighbours. Despite the decades-long policy of phasing out nuclear power, which has now been completed, the German nuclear industry is still very much in a position to support the climate policy of our neighbours in the area of nuclear power and to serve a promising business segment.

It is time for the German government to leave the trenches of the past, to recognise the value of nuclear energy for the climate policy of other countries and, accordingly, to handle or change export regulations and export promotion in such a way that both the local industry and the efforts of other countries to reduce emissions are supported. The currently planned introduction of a climate policy Sector guideline for export promotion would be a suitable moment for this and the Taxonomy Ordinance of the EU, from which it would simply not be necessary to deviate, and Annex II of the Climate Change Sector Understanding of the OECD offer a suitable framework for this.

In addition to dismantling, another area of nuclear technology in Germany is the entire field of waste management and disposal, from conditioning and interim storage to final disposal. However, while dismantling should be completed by around 2040, the duration of interim storage and disposal is expected to be significantly longer. In the case of high-level radioactive waste, recent analyses suggest that periods well into the next century are to be expected, which are well beyond the usual corporate planning horizons. As part of the reorganisation of responsibilities for waste disposal, two state-owned companies were founded under the ownership of the federal government, the Federal Company for Final Disposal mbH (BGE) and the BGZ Gesellschaft für Zwischenlagerung mbHwhose responsibilities are reflected in their names. These two companies are the dominant players in this field, with responsibility for most interim storage facilities and waste storage facilities and the construction of a logistics centre for the Konrad repository and for the construction and subsequent operation of the Konrad repository, the closure of the Morsleben repository, the remediation of the Asse mine and the selection of a site for a repository for high-level radioactive waste and irradiated fuel elements. The BGE also includes BGE TechnologyThe repository technology is also developed in international co-operation projects. All three companies also conduct research in their area of responsibility.

Due to the long time horizon, a particular challenge in the waste management sector is undoubtedly maintaining and expanding the expertise required to fulfil the waste management task in a country that has abandoned the use of nuclear power.

A major supplier of waste treatment plants for radioactive waste, as well as other hazardous waste including natural radioactive substances, is the NUKEM Technologies. In addition to concepts, feasibility studies and planning services, we can also build plants and even complete waste treatment centres. Design and planning services for interim and final storage facilities can also be provided. The Bilfinger Noell offers a comprehensive range of waste treatment and waste conditioning equipment, including sampling, sorting, dismantling, cementing, decapping equipment, double lid airlocks, manipulators, decontamination equipment, high pressure presses, water purification and protective enclosures.

A comprehensive portfolio of services for the planning and construction of facilities for the conditioning and storage of radioactive waste and irradiated fuel elements is offered by Iqony a successor company to STEAG, which planned and built some of the decentralised interim storage facilities at the nuclear power plant sites. WTI was commissioned with the remaining on-site interim storage facilities. Kraftanlagen Heidelberg offers waste treatment, loading and packaging campaigns and also has unique expertise in Germany for vitrification facilities for liquid high-level radioactive waste from reprocessing, in which the company works together with the Institute for Nuclear Waste Management at KIT. This technology has never been used commercially in Germany and has not been used in this country since the Karlsruhe vitrification facility completed its work. In this respect, it is a good example of maintaining industrial expertise without a domestic market, a situation that will gradually characterise large parts of the industry and its skills.

In addition to power generation in nuclear power plants, there are a variety of applications for nuclear technology in medicine, industry, research and development and agriculture. Radioisotopes are used as radiation sources in numerous applications in these areas, in medical diagnosis and therapy, in non-destructive material and component testing, in level and flow measurement systems, in the improvement of material properties, in the sterilisation of medical products, food and blood products, in plant breeding and pest control. The internationally active Eckert & Ziegler Radiation and Medical Technology offers a wide range of both medical and isotope products. These include sealed radiation sources for brachytherapy, various radiopharmaceuticals, equipment for their production, gallium-68 generators, radiotherapy accessories and X-ray radiotherapy equipment. Eckert & Ziegler also manufactures equipment technology (hot cells) and devices for the sterilisation of blood, blood plasma, bone marrow etc. and offers a comprehensive range of radioisotopes as sealed radiation sources in various strengths for numerous applications.

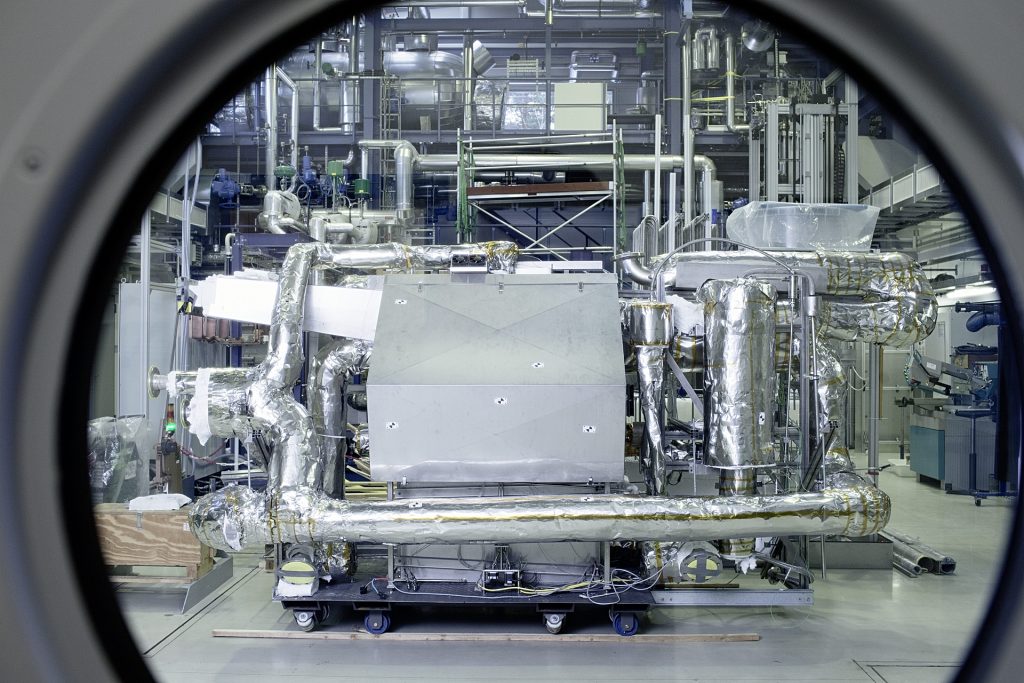

A supplier of hot cells for research and industry is also Power plants Heidelbergwhich are also involved in fusion technology. A tritium handling system and the ITER WDS (Water Detritiation System) are being developed for the ITER fusion research facility currently under construction. Concept and detailed planning for the ADS (Atmosphere Detritiation System) and for the associated hot cells at ITER are also being carried out, as well as conceptual design studies for the fuel cycle architecture of the DEMO tokamak demonstration power plant as the successor to ITER. Feasibility studies for the balance of plant and, above all, the development of a concept for a power conversion system are also being carried out for DEMO, one of the major engineering and industrial challenges that are decisive for the utilisation of fusion technology. Planning services are also provided for CERN, for example for the Large Hadron Collider (LHC) itself, the main experimental device, and for the ATLAS experiment located there.

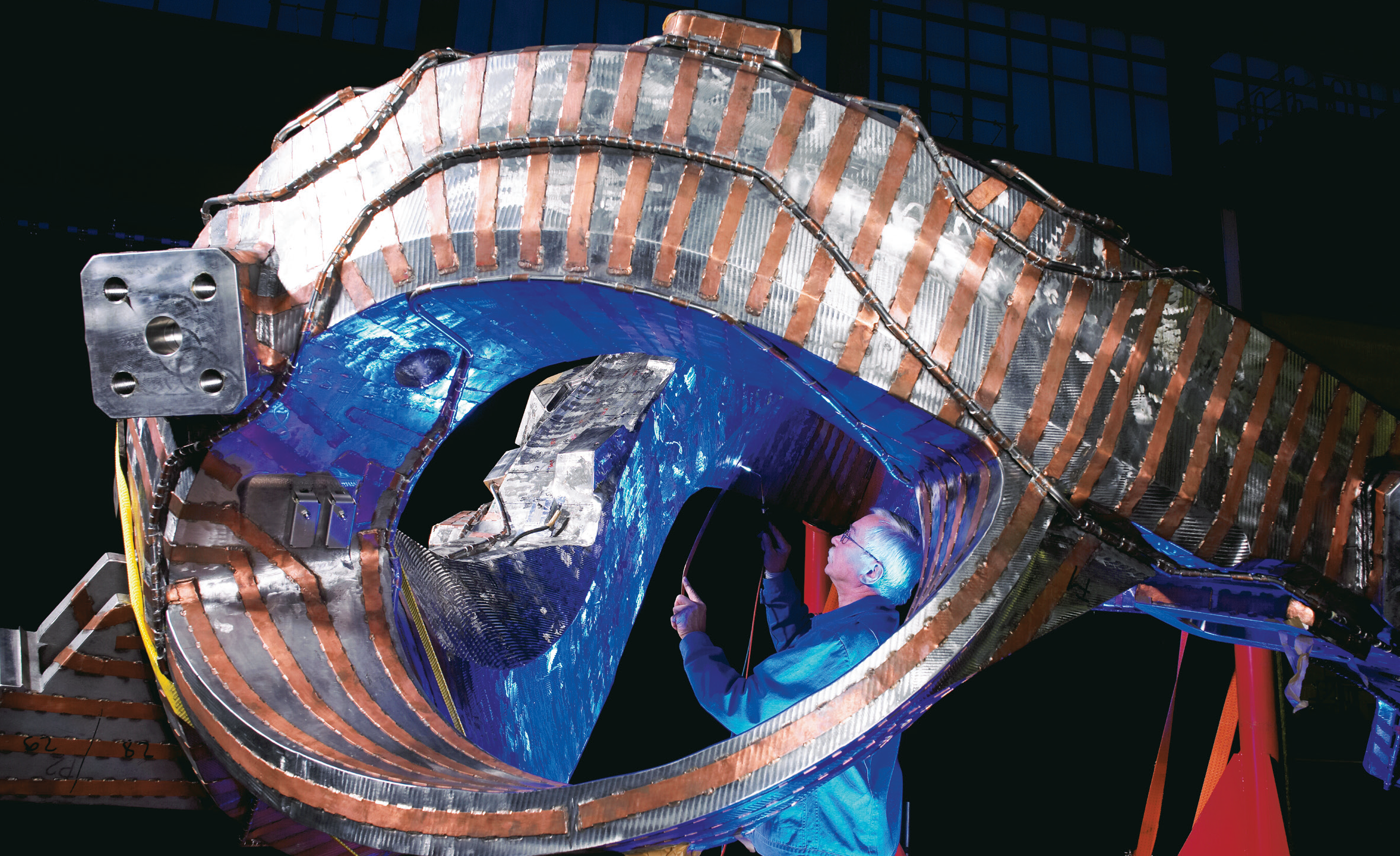

The Bilfinger Noell GmbH is also a supplier to major European research facilities, including manipulator carrier systems for the Joint European Torus (JET), a leading facility for fusion experiments, and a transport system for the LHC at CERN. The company has particular expertise in superconducting magnet systems and the associated cryogenic auxiliary systems, which have been provided for a number of international research facilities and the JT-60 and ITER fusion experiments. Analyses of the magnet systems were prepared for JET, a system is being developed for DEMO and Bilfinger Noell was also involved in the magnetic coils for Wendelstein 7-X, so that a collaboration with the stellarator start-up Proxima Fusion has now been initiated.

Virtually all of the companies mentioned have expertise in radiation protection by virtue of their activities in nuclear technology and due to regulatory requirements. However, some have radiation protection services as one of their business areas in the nuclear technology/nuclear energy sector. These include NUKEM Technologies, Kraftanlagen Heidelberg, Siempelkamp NIS, Safetec, Brenk Systemplanung, Höfer & Bechtel, iUS, Dornier Group, SAT Kerntechnik and Orano NCS. These services are not only required in connection with nuclear energy, interim and final storage, but also in nuclear medicine and in all applications of ionising radiation or in connection with NORM materials and environmental monitoring, and in future also in the field of nuclear fusion. So it really is a very universal ongoing task.

Nuclear technology research and teaching facilities in Germany are indispensable for securing and developing expertise in all nuclear technology tasks and topics, as well as for training highly qualified personnel to meet the demand for skilled labour and for the technical and scientific development of the sector. Although somewhat reduced in recent years, there is still considerable substance and sufficient "critical mass" in the German nuclear research landscape to produce enough graduates and participate in international research projects and programmes. It is pleasing to note that student numbers have recently started to rise again. A few institutions are mentioned here as examples.

Technical University of Munich

At the Technical University of Munich, the Chair of Nuclear Technology with the research focus on reactor safety research, experimental thermohydraulics, radiation applications in medicine and nuclear reactor and nuclear fuel designs of the future as well as the research reactor operation of the FRM II and the Radiochemistry Munich the TUM Centre for Nuclear Safety and Innovation which aims to increase the visibility of these competences and the infrastructure, maintain Germany's international reputation in nuclear issues and ensure the preservation and further development of nuclear expertise. (see also the description under "Research and Chairs")

Max Planck Institute for Plasma Physics

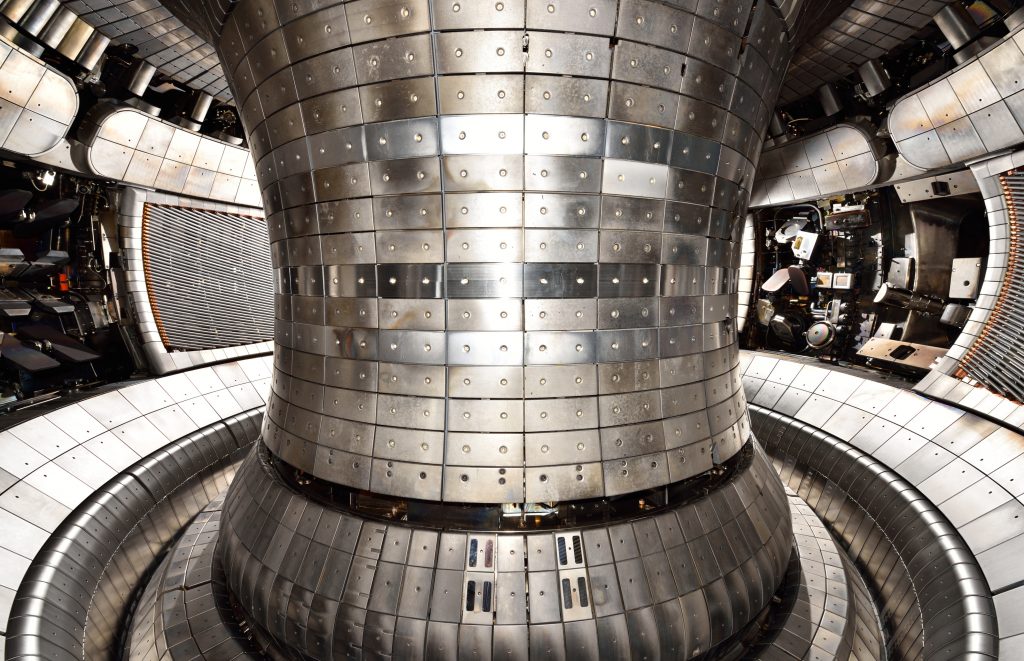

A major research facility for nuclear technology, but outside the field of nuclear power/nuclear fission, is the Max Planck Institute for Plasma Physics (IPP), one of the most important nuclear fusion research facilities in the world. With its own fusion experiments ASDEX upgrade and Wendelstein 7-X as well as its involvement in the Joint European Torus (JET) in the UK, the JT-60SA tokamak in Japan, the ITER project and the preliminary stages of DEMO, IPP has a leading position in magnet confinement fusion with the tokamak reactor concept and a leading role in the stellarator concept. The research topics are tokamak scenario development, physics of the plasma edge, plasma-wall interaction, ITER technology and diagnostics, tokamak theory, numerical methods in plasma physics, stellarator dynamics and transport, stellarator heating and optimisation as well as stellarator theory.

Karlsruhe Institute of Technology

At the Karlsruhe Institute of Technology - formerly the Karlsruhe Nuclear Research Centre - nuclear technology has long ceased to be a focal area, but with the Institute for Neutron Physics and Reactor Research (INR) and the Institute for Nuclear Waste Management (INE) continues to conduct cutting-edge research in the fields of safety analyses of nuclear facilities and fusion or safe dismantling of nuclear facilities and repository safety research. The INR specialises in reactor physics and dynamics, plant development, system dynamics and safety, thermal-hydraulic simulations

and optimisation, neutronics and nuclear data, measurement technology and experimental methodology as well as the design and analysis of nuclear components, production and qualification. At the INE, which shares the professorship with the Institute for Technology and Management in Construction (TMB) The Nuclear Technology division works on the dismantling of conventional and nuclear structures, repository systems and components, radiochemistry, radionuclide speciation and analytics. Both institutes have research facilities and experimental equipment. In addition, the Institute for Applied Thermofluidics (IATF)which deals with innovative reactor systems and in the field of nuclear fusion with thermohydraulics and thermomechanics, diagnostics and development of high-resolution measurement methods, system dynamics as well as neutron physics and nuclear data and the Institute for Thermal Energy Technology and Safety (ITES) which conducts research into heat storage and transfer using water, liquid metal and liquid salt, magnetohydrodynamics for fusion, computational fluid dynamics and analysis and decision support for critical infrastructure and radiological accidents. (see also the description in "Research and Chairs")

Helmholtz Centre Dresden-Rossendorf

At the Helmholtz Centre Dresden-Rossendorf, once home to the most important research reactor in the GDR and the second research reactor in Germany, nuclear technology expertise is being developed at the Institute for Fluid Dynamics with a focus on reactor safety research. The main areas of research are experimental thermofluid dynamics, magnetohydrodynamics, computational fluid dynamics and transport processes at interfaces. The institute has the TOPFLOW thermohydraulic test facility. The Institute of Resource Ecology (IRE) conducts research on long-lived radionuclides in bio- and repository systems and on the safety of nuclear reactors. In the field of medical applications, the Institute for Radiooncology which is working on improving the treatment of cancer through biologically individualised, technologically optimised radiotherapy as well as the Institute for Radiopharmaceutical Cancer Researchwhich conducts research into the molecular imaging and therapy of tumours.

research center Julich

At Forschungszentrum Jülich, the Institute of Energy and Climate Research has four research areas, Plasma physicsThe research focus is on fusion research with a focus on plasma-wall interaction, theories and modelling, material tests, materials and components as well as the work area six, Nuclear waste disposalwhich conducts research into repository safety, reactor safety, highly radioactive waste, hydrometallurgical separation processes for highly active waste for optimised repository conditioning, radionuclide transport, safeguards and security.

University of Stuttgart

At the University of Stuttgart, nuclear technology research at the Institute for Nuclear Energy and Energy Systems (IKE) is being bundled. At the IKE, the two departments of Reactor Safety, Systems and Environment and Energy Conversion and Thermal Engineering conduct research into micro-modular reactors, machine learning in accident analysis and accident mitigation, innovative passive safety systems for nuclear power plants, the properties of systems with supercritical fluids, the validation of existing codes for accident simulation for light water SMRs and the further development of simulation models for the late accident phase to improve severe accident strategies. (see also the description in "Research and Chairs")

Ruhr University Bochum

At the Ruhr-Universität Bochum, nuclear technology is part of the Institute for Energy Technology in the AG Plant Simulation and Safety (PSS). The research focuses on the further development, optimisation and validation of international accident analysis codes and their physical model basis, accident analyses and possibilities of accident prevention (Severe Accident Management Guidelines (SAMGs)), development of data sets for the simulation of European power plant types, CFD analyses and the investigation of current events.

An overview of nuclear technology within and outside of nuclear power shows that there is a diverse and competent industry in Germany, which in its entirety forms something of an economic and technological hidden champion of its own kind. If you look at the astonishing breadth of industrial and scientific expertise in nuclear technology in Germany, a country that is phasing out nuclear power, it would be hard to believe that the entire sector employs fewer than 30,000 people in industry, state waste management companies, research, authorities, expert organisations and decommissioning utilities. Nuclear technology in Germany is clearly not an employment giant, but it is a productivity and foreign trade giant that is well suited to improving the image of the German economy and industry abroad, which has unfortunately been tarnished in some cases.

At a time of much lamented weakness in important branches of industry, nuclear technology today offers good development opportunities in an environment characterised by the upturn in nuclear energy in a large number of countries and broadening technical horizons. With the high proportion of know-how and know-why in its value creation, nuclear technology is not so heavily dependent on energy and material costs and its basic structure as a sector of mechanical and plant engineering means that its field of activity is one that has traditionally been one of the strengths of the German economy, unlike the manufacture of mass products in sectors characterised by cost and price degression. In other words, the value of the technical, scientific and industrial capital stock of nuclear technology for the German economy is far greater than the current number of employees would suggest.

This alone should actually be a reason for politicians to promote the industry in its foreign trade activities and not hinder it, as well as to maintain research and expand teaching in order to ensure the next generation of skilled workers for a sector that will soon be expanding. In addition, however, there are the aspects of maintaining long-term competence for the tasks still pending in Germany, the desire not to be left behind technologically in this area, while neighbouring countries - Sweden, for example, is now also expanding nuclear energy with proven and new technologies and, last but not least, the desire to incorporate the special safety culture in nuclear technology that has grown in this country into international development. The final word should now be given to the German government's "Concept for Expertise and Young Talent Development for Nuclear Safety", which is hereby recalled and which states:

"Industry, trade and service providers participate in national and international nuclear safety research and contribute to the development of expertise, the promotion of young talent and international discussion. At the same time, they contribute to the further development of the state of the art in science and technology in the above-mentioned fields in concrete applications at home and abroad. This has also enabled in-depth insights and independent findings with regard to security-related developments abroad. In addition to the international networking of research, teaching, authorisation and supervision, the activities of German companies abroad formed an important basis for the dissemination and practical implementation of German understanding of security abroad."