New

General

Nuclear power plants in Germany

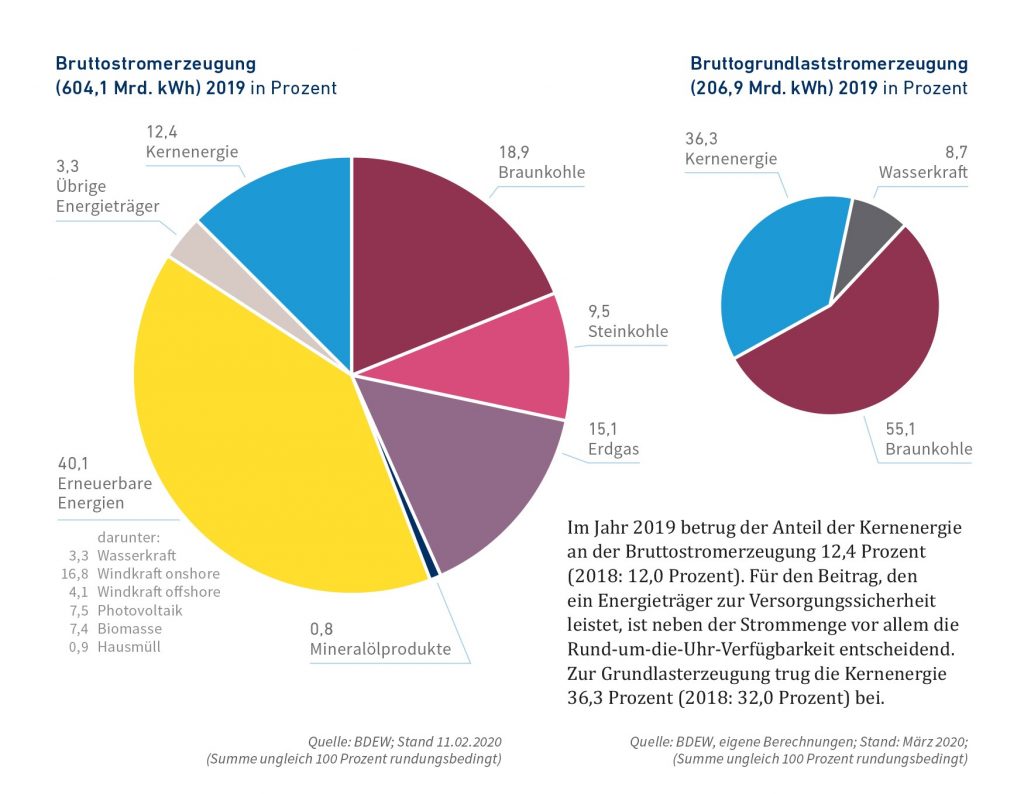

German nuclear power plants generated a total of 64.372 billion kWh of electricity (gross) in 2020.

In 2021, six nuclear power plants with a gross capacity of 8,545 MWe were in operation.

Overall, gross electricity generation in Germany amounted to 567.4 billion kWh in 2020 (2019: 603.8 billion kWh), of which nuclear energy accounted for 11.3 per cent (2019: 12.4 per cent).

Since the start of nuclear energy utilisation in Germany in 1961, around 5,490 billion kWh of gross electricity had been generated in nuclear power plants by the end of 2020.

Nuclear power plants worldwide

35 countries worldwide rely on nuclear energy (as of 12/2018)

In December 2018, 451 nuclear power plants with a gross installed electrical capacity of around 425 GWe were in operation in 31 countries and 53 nuclear power plants with a gross electrical capacity of around 58 GWe were under construction in 18 countries.

At the end of 2018, 126 nuclear power plants were in operation in the European Union (EU-28).

Uranium

Uranium is an important raw material in our lives. Mostly utilising nuclear fission, uranium is used in medicine, industry and research. However, its main application is in power generation. Due to its global availability and good storability, the worldwide supply of uranium is secured for a long time.

Further information on the use of uranium

Medicine

Diagnosis and cure of tumours

The FRM II research reactor at the Heinz Maier-Leibnitz Zentrum (MLZ) in Garching near Munich will in future use neutron radiation to produce technetium, which is often used in medicine.

Uranium plays a material role in the production chain of the isotope technetium-99m (Tc-99m), which is produced by the decay of molybdenum-99. This isotope is most commonly used in nuclear medicine for diagnostics and cancer treatment. This is because it has a very short half-life of six hours and the low radiation intensity minimises radiation exposure for patients. This short half-life means that the radioisotope most commonly used in medicine cannot be stored. The entire production chain must therefore run quickly and be well coordinated in order to supply hospitals with the necessary quantity of Tc-99m in good time. Around 30 million tests are carried out worldwide every year.1 In Germany alone, 60,000 per week2, which corresponds to around one tenth of global demand. It is used to examine the thyroid gland or to diagnose diseases of the lungs, heart, liver, gall bladder and skeleton. In future, half of Europe's demand for technetium-99m is to be produced in Garching in a new building at the FRM II research reactor.

Food

3,000 new plant varieties

With the help of gamma radiation, new plant species are now being bred to counter population growth, for example new rice varieties.3 Bangladesh, for example, has been able to increase its rice production threefold in recent decades. Binadhan-7 is one of several rice varieties developed by scientists at the Bangladesh Institute for Nuclear Agriculture (BINA) with the support of the International Atomic Energy Agency (IAEA) and the Food and Agriculture Organisation of the United Nations. Like many other new rice varieties, Binadhan-7 was developed using the "Plant Mutation Breeding" process. Radioactive radiation is used to catalyse a natural mutation process in plant seeds. Over 3,000 plant varieties have already been bred worldwide using plant mutation breeding.

Against bacteria and mould

Radiation, which is generated indirectly through the use of uranium, is also used for sterilisation in modern industrial societies. This is because this high-energy particle radiation eliminates harmful microorganisms without producing radioactivity. The irradiation also increases the shelf life. In Germany, for example, dried spices are treated in this way. This is because spices and herbs grown in the wild can contain bacteria and mould. When sterilised with superheated steam, the vitamin content, colours and flavourings suffer. Sterilisation by irradiation preserves vitamins and flavours. Packaging is also sterilised to prevent pathogens from entering the food later on. Empty yoghurt pots, for example, are sent to a sterilisation plant. Not every pot individually: Ionising radiation works through many layers of material. This means that entire pallets of yoghurt pots can be sterilised at the same time.

Neutron research

Neutrons: Looking inside aeroplane walls

Unlike in a nuclear power plant, in neutron research the surplus neutrons from the nuclear fission of uranium are the desired product, while the heat is an undesirable by-product. Neutrons are small, electrically neutral particles. They penetrate deep into materials. Researchers can use them to analyse materials and change their molecular structure.  In materials research, researchers investigate turbines, car engines and aircraft walls, for example. The focus here is on the influence of extreme stresses such as temperature, pressure or tension. The aim is to detect damage and develop materials that are more durable, lighter and more cost-effective.

In materials research, researchers investigate turbines, car engines and aircraft walls, for example. The focus here is on the influence of extreme stresses such as temperature, pressure or tension. The aim is to detect damage and develop materials that are more durable, lighter and more cost-effective.

Uranium as a catalyst

A process is currently being researched in which depleted uranium is used as a chemical catalyst to produce hydrogen from water using electricity. Uranium catalysers could also improve the use of carbon dioxide and nitrogen as raw materials. One example is the conversion of carbon dioxide into the energy sources ethanol or methanol. Carbon dioxide is a greenhouse gas and is produced during energy generation, as exhaust gas in transport or in the steel and cement industries. The chemical conversion of carbon dioxide is a very energy-intensive process. Conversion with uranium reduces this energy requirement.  The production of ammonia from nitrogen would also be possible with the help of uranium catalysts. This is because around 1.4 per cent of global energy consumption is currently used for the production of ammonia alone. Ammonia is a basic chemical and is used in fertilisers, for example.

The production of ammonia from nitrogen would also be possible with the help of uranium catalysts. This is because around 1.4 per cent of global energy consumption is currently used for the production of ammonia alone. Ammonia is a basic chemical and is used in fertilisers, for example.

Heat from uranium

Heat from uranium

The most important application of uranium worldwide is its use in nuclear power plants to generate electricity. Energy is generated through nuclear fission and chain reactions. In a nuclear power plant, heat is the desired main product.

A classic steam power process using a steam turbine and generator then produces the electricity. Uranium is not a fossil fuel, so practically no CO2 is produced when it is used. In this respect, uranium is similar to hydropower. The share of uranium fuel in the cost of generating electricity from nuclear energy is relatively low and is between 10 and 15 per cent on average internationally. In December 2016, 450 nuclear power plants were in operation in 31 countries and 58 nuclear power plants were under construction in 15 countries. At the end of 2016, 129 nuclear power plants were in operation in the European Union (EU-28).

Nuclear reactors in nature

It is interesting to note that nuclear fission and chain reactions cannot only be initiated by humans. There were also natural reactors: uranium deposits in which nuclear fission and chain reactions occurred due to a natural concentration of uranium. In Oklo, Gabon (Central Africa), 14 natural reactors were active 1.5 to 2 billion years ago - for around 500,000 years. They generated about as much thermal energy as an average nuclear power plant produces in four years.

Occurrence

Uranium for millennia

Uranium does not occur in a pure form in nature. Uranium is only found in minerals. Around 230 of these so-called uranium minerals are known. Traces of uranium can be found not only everywhere in the soil, but also in the Oceans. The average content in the earth's continental crust is around three grams per tonne. This makes uranium about as common as tin. As a result of geological processes, ores with higher concentrations of uranium have formed on all continents and in many countries, making economic exploitation worthwhile. Today, ores with a uranium content of at least 0.1 to 0.5 per cent are used commercially.

The mineral uraninite, also known as "pitchblende", has the highest uranium content. It has a uranium content of up to 20 per cent. As uranium can be found in many places around the world, the security of supply for uranium is higher than for other strategically important raw materials. The global demand for uranium in 2015 was around 56,600 tonnes. Global uranium resources are sufficient to secure supplies for nuclear power plants for many decades - even if the number of nuclear power plants worldwide increases significantly.

Resources

The "Red Book", which is published jointly by the OECD's Nuclear Energy Agency (NEA) and the IAEA, states that total uranium resources amount to around 15 million tonnes of uranium (tU). The resources known today and extractable with current technology at a maximum of 130 $ per kilogramme of uranium (kg U) are around 5.7 million tU. If the in-situ extraction method is taken into account, the resources increase to 7.4 million tU.

New deposits are being found through continuous uranium exploration. There are also other resources, for example an estimated nine million tonnes of uranium in phosphate deposits or several million tonnes in black shale. Around four billion tonnes of uranium are dissolved in seawater. The total conventional resources alone would cover global uranium requirements for more than 200 years.

Promotion

Mine ventilation, spoil heaps, sedimentation basins

The same techniques are used for uranium mining as for other minerals: open-cast or underground mining. In many mines, uranium is not extracted as the main product, but as a by-product - in the Australian Olympic Dam copper mine alongside gold and silver.

As uranium is radioactive, the same limits apply for miners in uranium mining as for nuclear power plant personnel. No unauthorised quantities of radioactive substances may be released into the air or water from the exhaust air of the mine ventilation system, the spoil heaps and the settling basins for the sludge from ore processing. Mine wastewater is monitored and purified for radioactivity and the content of toxic heavy metals.

Drilling the ore body

One method of uranium extraction is becoming more and more widespread: in situ leaching. In this process, the ore is not mined, but holes are drilled into the ore body and a solvent - usually diluted sulphuric acid - is pumped in. This dissolves the uranium in the ore body and the uranium-containing solution that forms is pumped out of the deposit through other boreholes. Around half of the world's uranium production is now extracted using the in-situ solution process. This process is more environmentally friendly and economical than conventional extraction and enables better utilisation of the deposits. Interference with nature is minimised, overburden is significantly reduced and unwanted, sometimes toxic substances found at depth are not extracted.

Processing

What does "enrich uranium" mean?

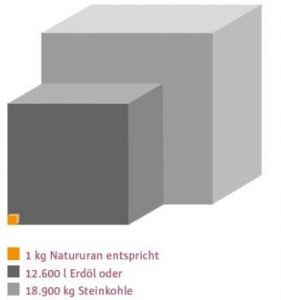

Uranium is "enriched" in an enrichment plant. Enrichment means that the proportion of the fissile isotope uranium-235 in uranium is increased to three to five per cent. This is because natural uranium consists of various uranium isotopes and the proportion of uranium-235 is only around 0.7 per cent. An increase is necessary to achieve a chain reaction in light water reactors and to utilise the nuclear fuel for several years. The basic procedure of the enrichment process is as follows: a gas stream of natural uranium is fed into a centrifuge and divided into two partial streams by centrifugal force. The fissile uranium-235 is largely removed from one stream (depletion).

The other part of the stream is enriched with these particles. The depleted uranium is not waste but a valuable material and can be used in specific reactors or as ballast material in ship keels, for example.

Uranium tablets

The enriched uranium (UF6) is converted into uranium dioxide (UO2) and the UO2 powder is pressed into cylindrical tablets. These are filled into fuel rods made of the metal alloy Zirkaloy. The fuel rods are welded together and assembled into fuel rod assemblies (fuel elements).

The enriched uranium (UF6) is converted into uranium dioxide (UO2) and the UO2 powder is pressed into cylindrical tablets. These are filled into fuel rods made of the metal alloy Zirkaloy. The fuel rods are welded together and assembled into fuel rod assemblies (fuel elements).

Fuel assemblies are not "off-the-shelf" products. They are "customised" for the reactor in which they are to be used. The operator specifies the degree of enrichment of the nuclear fuel according to the planned operating mode of the reactor. Both natural uranium and enriched uranium are only slightly radioactive in all processing stages and forms in the supply chain. Therefore, there is no particular risk of radiation exposure during transport and storage.